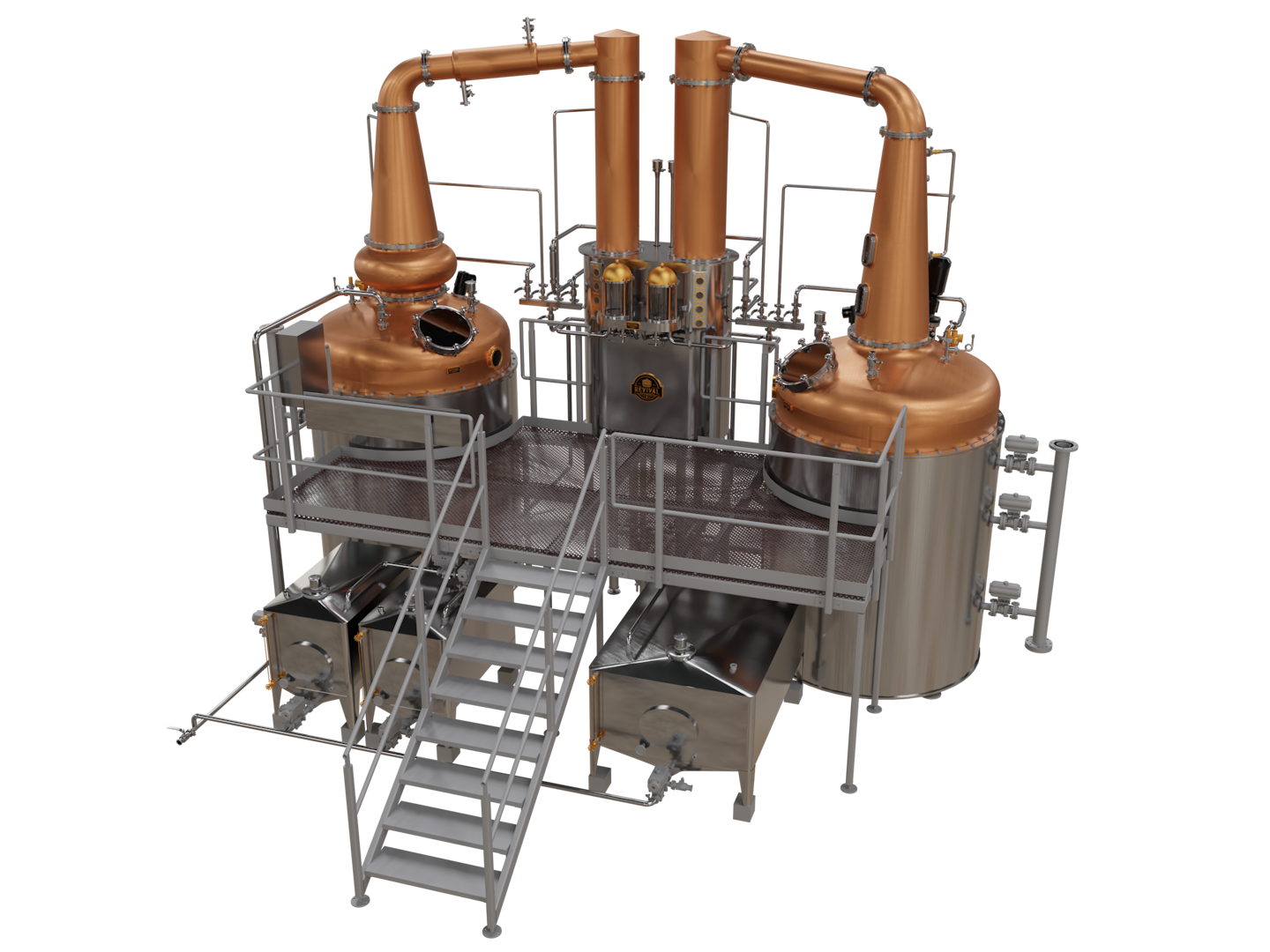

Whiskey stills

Whiskey is traditionally a two-step distillation process. A wash still (stripping still) and spirit still are used to produce traditional single malt whiskey. A hybrid still can produce whiskey in a single distillation with a rectification column. Larger distilleries use column stills or a combination of beer still and doubler to make whiskey production more efficient.

*The color configuration of our stills constitutes proprietary trade dress, and is a trademark of Revival Stillworks Ltd.

Options

types | FEATURES | SPIRIT RUN FREQUENCY |

|---|---|---|

STRIPPING STILL SPIRIT STILL | -2 STILLS -HIGHER PRODUCTION | -STRIPPING RUN EVERY DAY -SPIRIT RUN EVERY DAY |

SPIRIT STILL | -1 STILL -LOWER PRODUCTION | -STRIPPING RUN DAYS 1-3 -SPIRIT RUN EVERY 4th DAY |

HYBRID STILL | -1 STILL -SINGLE RUN DISTILLATION -SMALL FOOTPRINT | -SPIRIT RUN EVERY DAY |

CONTINUOUS PRODUCTION | FEATURES | |

|---|---|---|

COLUMN STILL | -ABILITY TO RUN CONTINUOUSLY 24-7 -SUITED FOR LARGE DISTILLERIES -HIGH PRODUCTION -BOURBON |

Configurations

Internal or External Heating

Electric Heating

Clean In Place (CIP)

Pot Still Shape

Spirit Head Shape

Foam Windows and Sensors

Lyne Arm Size and Angle

Mixers

Condensers

Columns

Automation

Whiskey is produced from grain mash. The grain mash can be fermented and distilled in a pot still (distilling on the grain) or it can be lautered and fermented into beer prior to distilling. Whether you are distilling "on-the-grain" or not, will influence various aspects of your pot still.

For on-the-grain distillation a pot still with a mixer is preferred to prevent scorching of the grain on the heating surfaces. External steam jackets are also preferred so that the contents of the pot still can be emptied and cleaned more effectively.

For a lautered beer, a mixer is not necessary and internal heating coils or plates can be used due to the lack of solids in the still. Various grains can be used including malted barley, rye, corn or wheat. The type of grain that you choose can affect the amount of foam that will build up in your still while you are distilling. This foam can be dealt with using de-foaming agents to break the surface tension of the bubbles, or you can allow for sufficient head space in your still and use visual foam window indicators or foam sensors to regulate the foam height.