AUTOMATION

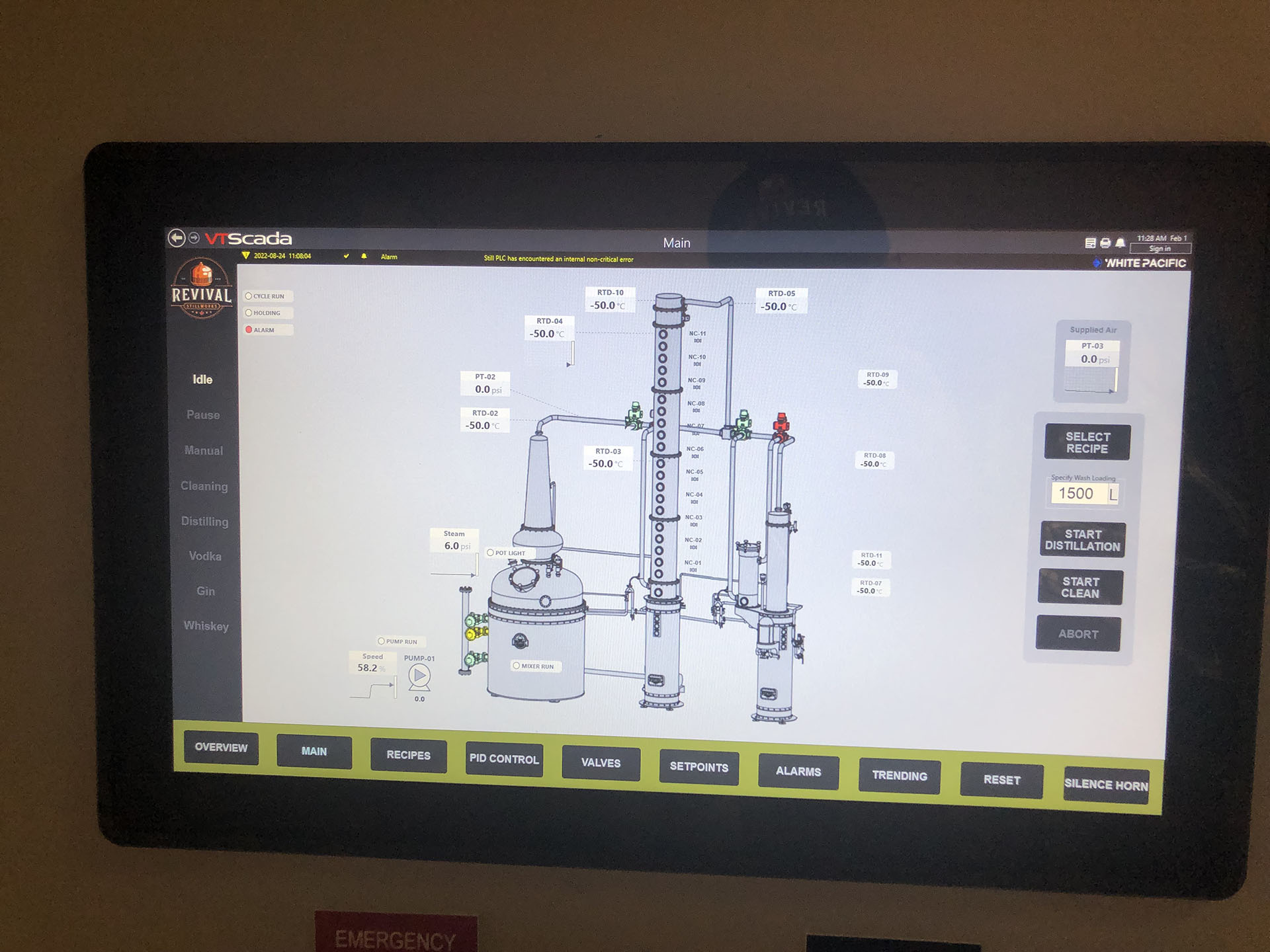

Automating your distilling process can improve product consistency, increase product yield and enhance labor productivity. Whether you want to automate your entire distilling process or if you want to monitor your distillery remotely, Revival can tailor an automation solution to suit your goals.

Automation packages include large touch screen control interfaces, and reliable PLC controls. Our Wi-Fi module option allows for remote monitoring and management of your distillery. Contact us to learn more about how automation may help your distilling operation.

OPTIONS

type | FEATURES |

|---|---|

FULL AUTOMATION | -ALL PROCESSES AUTOMATED -tOUCH SCREEN CONTROL -abv MONITORING USING ALCOHOL SENSORs -AUTOMATIC CUTS SEPARATION |

PARTIAL AUTOMATION | -oNLY DESIRED PROCESSES AUTOMATED -TOUCH SCREEN CONTROL OF VALVES, PUMPS, MIXERS, LIGHTS, ETC. -TEMPERATURE BASED abv MONITORING -MANUAL CUTS SEPARATION |

TOUCH SCREEN CONTROL | -nO AUTOMATED PROCESSES -TOUCH SCREEN CONTROL OF VALVES, PUMPS, MIXERS, LIGHTS, ETC. -MONITORING AND DATA LOGGING CAPABILITY |

CONFIGURATIONS